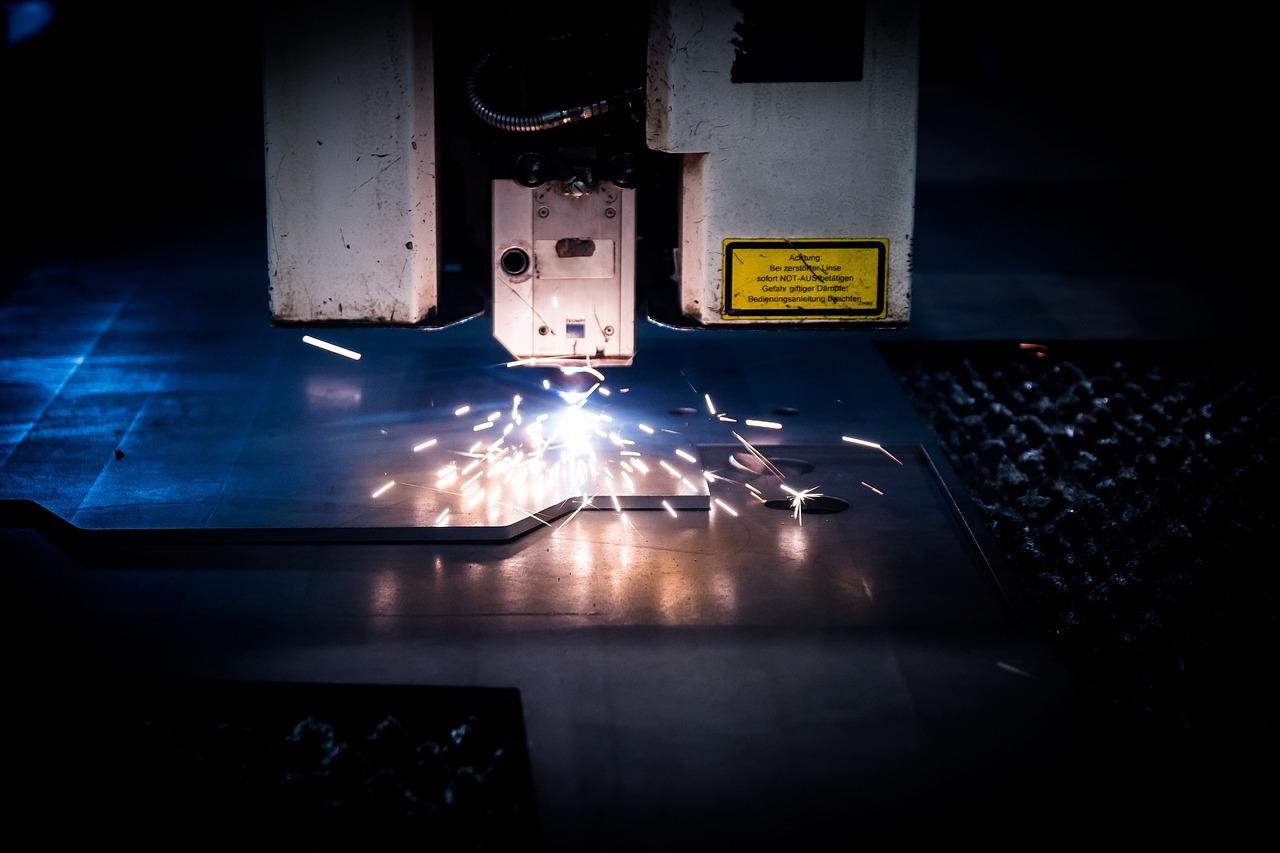

In the fast-evolving world of manufacturing, brass laser cutting has emerged as a revolutionary technology that enables unparalleled precision and efficiency. As industries demand intricate designs and tighter tolerances, this cutting-edge process provides a solution that delivers both quality and speed. From automotive components to decorative art pieces, brass laser cutting is redefining standards in fabrication. In this blog, readers will discover how laser profiling complements brass laser cutting to create seamless applications and transform workflows across industries.

Understanding Brass Laser Cutting Technology

At its core, brass laser cutting uses high-powered lasers to cut and shape brass materials with remarkable accuracy. Unlike traditional cutting methods, lasers produce clean edges with minimal material wastage, resulting in a cost-effective manufacturing solution. The ability to achieve fine details is ideal for industries like electronics, where precision is paramount.

One notable advantage is its versatility. Whether it’s thin brass sheets or intricate geometries, laser cutting adapts to diverse project requirements. This flexibility is a game-changer for manufacturers seeking customized solutions in sectors ranging from architecture to aerospace.

The Role of Laser Profiling in Brass Fabrication

Laser profiling is a critical aspect of the brass laser cutting process. It allows manufacturers to extract the desired contours and shapes efficiently, ensuring all designs meet exact specifications. Through advanced software integration, materials can be tailored with uniform consistency across batches. This is particularly important for industries that rely on mass production without compromising on quality.

For example, laser profiling ensures smooth finishes in brass components used in medical devices, where safety and performance are non-negotiable. By offering enhanced precision, manufacturers can eliminate the need for labor-intensive secondary processes, thereby saving time and resources.

Benefits of Brass Laser Cutting for Every Sector

1. Unmatched Precision

Achieving designs with intricate details is easier than ever. Brass laser cutting enables manufacturers to create aesthetically pleasing and functional components for various applications.

2. Reduced Material Waste

Laser technology ensures minimal waste since it targets specific cutting zones without impacting surrounding areas. This saves resources and enhances sustainability.

3. Speed and Efficiency

Combining brass laser cutting with laser profiling accelerates production timelines without sacrificing quality. Businesses can handle tight deadlines while maintaining product integrity.

Closing Thoughts

Brass laser cutting, enhanced by laser profiling, is not just a process—it’s a gateway to innovation. Industries are leveraging this transformative technology to meet modern demands for precision, efficiency, and sustainability. By adopting laser-based solutions, manufacturers can stay ahead of the competition while delivering cutting-edge results. Whether you are crafting decorative brass art or vital industrial components, these advancements are setting the gold standard in manufacturing.